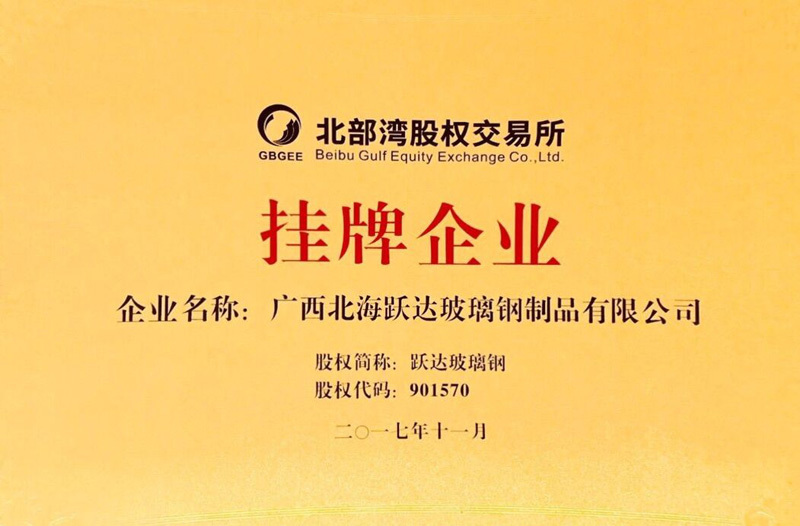

On the afternoon of November 24, 2017, the 38th listing ceremony for companies at the Guangxi Beibu Gulf Equity Exchange, hosted by the Guangxi Beibu Gulf Equity Exchange, was successfully held in Beihai. This event featured a special guest, an investment consulting lecturer from Guangxi Changxin Investment Co., Ltd., who focused on the topic of "Designing Business Models for Enterprises." The lecturer provided a detailed and vivid explanation of business model design in the context of enterprise development, combining theory with practical case studies. Nearly 222 listed companies, including Guangxi Beihai Yueda FRP Products Co., Ltd., participated in the awarding ceremony, with approximately 300 people attending the event.

2018/09/11

Congratulations on the relocation of Guangxi Beihai Yue Da FRP Products Co., Ltd.

Beihai Yueda FRP Products Co., Ltd. was relocated in November 2014 from its original site at Hong Kong Road, Beihai Industrial Park to a new location 200 meters north of the intersection of Hong Kong Road and Southwest Avenue, Beihai Industrial Park. We welcome new and old customers to visit and guide us at our factory.

2018/09/11

Market Analysis of FRP Pipes: The Top Ten Advantages of FRP

There are two forming methods for fiberglass pipes: one is fixed-length pipes, and the other is continuous pipes. Fiberglass pipes have a series of excellent characteristics such as corrosion resistance, pollution prevention, pest resistance, heat resistance, frost resistance, and good designability, making them widely used in the water supply and drainage industry. Similar to container forming, but for pipes, there is no need for end caps. Generally, a winding angle greater than 54.7 degrees is used at the pipe ends, returning to nearly 90 degrees, resulting in a high accumulation of fibers at the pipe ends. This utilizes the circumferential strength and rigidity of the joints to ensure sealing performance. For large-diameter long-distance transport pipes, O-ring socket connections are used, with one end of a single pipe made in a male and the other in a female form. Short-distance above-ground process pipelines mostly use adhesive connections. Process pipelines require a large number of fittings, such as tees and elbows. High-performance pipe systems and fittings are formed using continuous fiber winding, and the winding of fittings is much more complex than that of straight pipes and containers. Although multi-axis and even robotic winding machines for fittings have been developed, they cannot be widely promoted in the manufacturing of industrial fittings due to economic reasons. Therefore, the winding of fittings is mostly completed semi-manually. In buried large-diameter pipelines, sand-clamped pipes have been developed to reduce costs and improve resistance to external pressure, lowering the cost of pipes by about 50%. Ten Advantages of the New Building Material - Fiberglass Compared to pipes made of other materials, fiberglass pipes have the following significant advantages: 1. Corrosion Resistance and Pollution-Free Fiberglass pipes can resist the erosion of acids, alkalis, salts, seawater, untreated sewage, corrosive soils or groundwater, and many chemical fluids. Fiberglass pipes have excellent characteristics such as being non-toxic, rust-free, odorless, causing no secondary pollution to water quality, and requiring no anti-corrosion treatment, which is why they are widely used in the water supply and drainage industry. 2. Pollution Prevention and Pest Resistance The surface of the pipes is made with unsaturated polyester resin, making it clean and smooth, preventing contamination by microorganisms such as mollusks and fungi in seawater or sewage, which can increase roughness, reduce flow cross-section, and increase maintenance costs. The pipes remain clean and as good as new for long-term use. 3. Heat Resistance and Frost Resistance At -30°C, fiberglass still has good toughness and very high strength, and can be used long-term in the range of -50°C to 80°C. Specially formulated resins can even work at temperatures above 110°C. 4. Lightweight, High Strength, Convenient Transportation and Installation Fiberglass pipes produced using fiber winding technology have a specific gravity of 1.65-2.0, only 1/4 that of steel, but the circumferential tensile strength of fiberglass pipes is 180-300 MPa, and the axial tensile strength is 60-150 MPa, similar to alloy steel. Therefore, their specific strength (strength/specific gravity) is 2-3 times that of alloy steel, allowing them to be designed to meet various internal and external pressure requirements. For pipes of the same diameter, the weight of fiberglass pipes is only about 1/2.5 that of carbon steel pipes, 1/3.5 that of cast iron pipes, and about 1/8 that of prestressed reinforced concrete pipes, making transportation and installation very convenient. Each section of fiberglass pipe is 12 meters long, reducing joints by two-thirds compared to concrete pipes. Its socket connection method allows for quick and easy installation, while also reducing lifting costs and greatly improving installation speed. 5. Low Friction Resistance and High Transport Capacity The inner wall of fiberglass pipes is very smooth, with low roughness and friction resistance. The roughness coefficient is 0.0084, while that of concrete pipes is 0.014 and cast iron pipes is 0.013. Therefore, fiberglass pipes can significantly reduce fluid pressure loss along the way and improve transport capacity. This can bring significant economic benefits: for the same transport capacity, projects can choose fiberglass pipes with a smaller inner diameter, thus reducing initial project investment; using pipes with the same inner diameter, fiberglass pipes can reduce head loss compared to pipes made of other materials, saving pumping costs. In addition, fiberglass pipes can shorten pumping time and reduce long-term operating costs. 6. Good Electrical Insulation Fiberglass is a non-conductor, and the electrical insulation of the pipes is excellent, with insulation resistance between 10^12 and 10^15 Ω.cm, making it most suitable for use in areas with dense power transmission and telecommunications lines and high lightning activity. The thermal conductivity of fiberglass is very low, only 0.23, which is one-fifth that of steel, providing excellent insulation performance for the pipes. 7. Good Wear Resistance A comparative test was conducted by rotating water containing a large amount of mud and sand in the pipes. After 3 million rotations, the wear depth of the inner wall of the pipes was as follows: steel pipes with tar and porcelain glaze coating were 0.53 mm, steel pipes with epoxy resin and tar coating were 0.52 mm, and fiberglass pipes after surface hardening treatment were 0.21 mm. This shows that fiberglass has good wear resistance. 8. Low Maintenance Costs Due to the aforementioned properties of corrosion resistance, wear resistance, frost resistance, and pollution resistance, projects using fiberglass pipes do not require anti-rust, anti-pollution, insulation, or thermal insulation measures and repairs. Buried pipes do not require cathodic protection, saving maintenance costs by over 70%. 9. Good Designability Fiberglass pipes can be designed and manufactured according to various specific requirements of users, such as different flow rates, different pressures, different burial depths, and load conditions, to create pipes of different pressure and stiffness grades. 10. Long Service Life and Comprehensive Benefits Laboratory simulation tests indicate that the service life of fiberglass pipes can reach over 50 years. Comprehensive benefits refer to the long-term effects formed by construction investment, installation and maintenance costs, service life, energy savings, and steel savings. The comprehensive benefits of fiberglass pipes are favorable, especially as the pipe diameter increases, the cost decreases. When further considering the long service life of buried pipes, which do not require annual maintenance, the comprehensive benefits are excellent. Beihai Yueda Fiberglass Products Co., Ltd. is a fiberglass production and research and development company with rich experience in this field. The fiberglass pipes, fiberglass cable protection pipes, and fiberglass water tanks produced are well-loved by everyone.

2018/09/11

With the increasing maturity of the fundamental research technology of fiberglass and the continuous introduction of advanced foreign equipment and technology, the domestic fiberglass industry has developed rapidly in recent years, with a continuous expansion of the varieties of gel coat resins. The continuous improvement in the variety and performance of gel coat resins has led to an expansion of their application fields. Currently, gel coat resins are used in many areas such as sanitary ware like shower trays, bathtubs, and countertops; the shipbuilding industry including yachts, lifeboats, and patrol boats; as well as in transportation, construction, entertainment, medical instrument casings, billboards, telephone booths, and security booths. Gel coat resins are divided into clear gel coats and colored gel coats. In the production process of these products, the vast majority of...

2018/09/11

The Top Ten Advantages of Fiberglass Reinforced Plastic in the Construction Materials Industry

There are two forming methods for fiberglass pipes: one is fixed-length pipes, and the other is continuous pipes. Fiberglass pipes have a series of excellent characteristics such as corrosion resistance, pollution prevention, pest resistance, heat resistance, frost resistance, and good designability, making them widely used in the water supply and drainage industry. Similar to container forming, but for pipes, there is no need for end caps. Generally, a winding angle greater than 54.7 degrees is used at the pipe ends, returning close to 90 degrees. The fiber accumulation at the pipe ends is high, utilizing the circumferential strength and rigidity of the joints to ensure sealing performance. The connection of large-diameter long-distance transport pipes uses O-ring socket connections, with both ends of a single pipe made in a male and female form.

2018/09/11

The Development of Fiberglass Products in Our Country

Beihai Yueda FRP Products Co., Ltd. has learned that fiberglass products are now widely used in urban water treatment, low-carbon weight reduction for ships, smart grid power equipment, marine tourism for boats, marine corrosion prevention and seawater desalination, metallurgical steel power desulfurization, corrosion prevention and safety in coal and stone mining, wind power, low-carbon vehicles, energy-saving construction, and decoration. At the same time, fiberglass products are increasingly applied in new technologies for making weapons, aerospace equipment, and more. It is not an exaggeration to say that the new fiberglass materials of the future will be another milestone in human development. The demand for fiberglass is expected to grow.

2018/09/11

recommend News