Basic Overview of Glass Fiber Reinforced Plastic (FRP) Sand-Laden Pipes

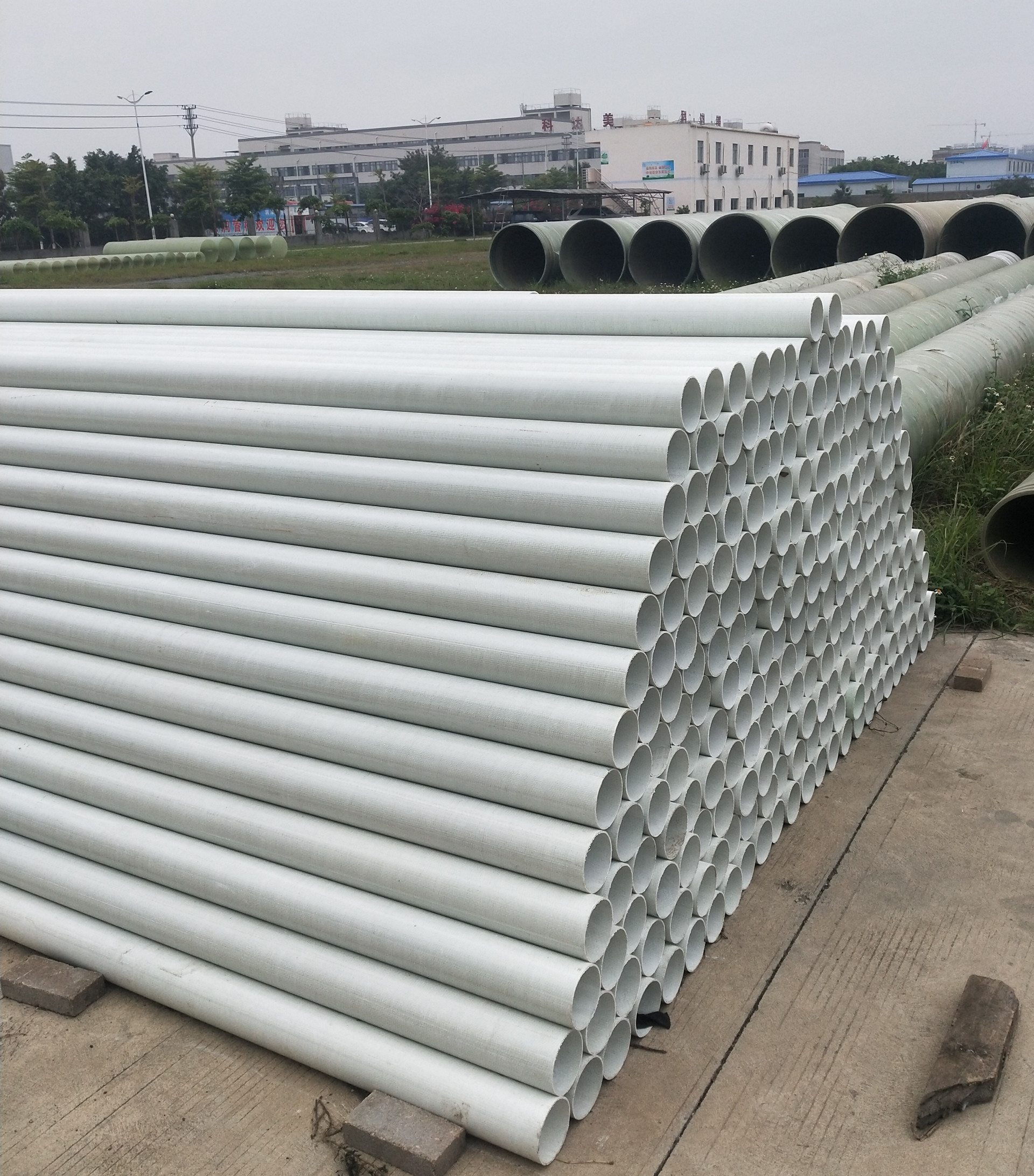

Glass fiber reinforced sand pipes, as the name suggests, are glass fiber pipes with sand wrapped around them. They are made by mechanically winding resin-based glass fibers layer by layer according to process requirements onto a rotating core mold, and evenly laying quartz sand as a sand layer between the fibers at a distance. Below is a detailed introduction.

2024/03/22

Yue Da Company starts work to welcome the Year of the Dragon, wishing for smooth and prosperous operations!

2024/02/21

The integrated prefabricated pump station made of fiberglass is a type of pump station that assembles equipment such as pumps, pipes, and fittings within a prefabricated fiberglass structure. It has the following characteristics and principles.

2023/12/26

The integrated fiberglass sewage pump station mainly assists in the drainage of rainwater and sewage in areas that are relatively remote from urban sewage networks, and it can also be used for water circulation in landscape lakes. The integrated fiberglass sewage pump station has many features. Its structure is compact, so it occupies a small area and can be installed discreetly without affecting the aesthetic of the surrounding environment. Installation is also relatively easy. The device has strong corrosion resistance, which can effectively extend its service life during use, requiring almost no daily maintenance and having a very low failure rate. The integrated fiberglass sewage pump station is an ideal alternative to traditional sewage pump stations. Typically, traditional pump stations have very strict requirements for planning and construction, requiring detailed planning for every aspect, and the installation of the pump station consumes a lot of manpower, material resources, and time. It requires setting up the construction site, pouring concrete, and waiting a long time for the concrete to harden. Then, the inlet point must be determined, drilled, and the necessary components installed. Completing these processes takes at least two months. During the construction of the integrated fiberglass sewage pump station, cooperation with contractors for various processes is also necessary, and these unnecessary steps will consume a lot of energy from planners, with varying quality of work from different contractors. With the integrated fiberglass sewage pump station, you can complete all processes including excavation, backfilling, compaction, connection, leakage testing, control system installation, trial operation, final debugging, and documentation within one or two weeks. This will save seven weeks of pump station installation time, achieving an 80% time-saving ratio. More importantly, it can solve a series of problems associated with traditional pump stations, such as leakage and corrosion, pump failures, sludge accumulation, environmental pollution, frequent maintenance, and high costs. Guangxi Beihai Yueda Fiberglass Products Co., Ltd. is a professional manufacturer of fiberglass products, and its products are well received by users. We welcome inquiries by phone.

2023/12/08

Identifying the Quality of Fiberglass Reinforced Plastic (FRP)

Fiberglass reinforced plastic (FRP) is a composite plastic made from glass fiber reinforced unsaturated polyester, epoxy resin, and phenolic resin as the matrix material. As a type of composite material, FRP has been widely used in various industries such as aerospace, railways, decorative architecture, home furniture, building materials, sanitary ware, and environmental sanitation engineering due to its unique performance advantages. So how can we distinguish the quality of fiberglass? 1. Material Selection The raw materials used in fiberglass are resin, glass fiber, and other auxiliary materials configured in suitable proportions. High-quality fiberglass uses high-quality resin with low viscosity, low exotherm, low shrinkage, fast curing, high compatibility, and bright gloss. 2. Comparison of Finished Products High-quality fiberglass products have no obvious cracks, fewer air holes, bright and pure colors, good transparency, excellent toughness, high strength, good surface finish, and long service life. In contrast, low-quality fiberglass products have visible cracks, more air holes, impure colors, and insufficient gloss. Their service life is also shorter. 3. Durability The true strength of fiberglass is also revealed during actual use. High-quality fiberglass may slightly darken in color after several years but remains intact without obvious damage. Low-quality fiberglass, however, cannot withstand the test of time; after a few years, it may show obvious damage such as corrosion, breakage, and air holes, and its shape may become uneven with severe color degradation and overall aging. Generally, high-quality fiberglass is expected to last for twenty years, while low-quality fiberglass may show signs of aging after just two years, leading to significant losses for customers. Therefore, we remind customers not to be tempted by low prices to choose low-quality fiberglass products, as this could lead to greater losses. Additionally, there are several other methods to identify the quality of fiberglass: 1. Dimensional tolerances (internal dimensions within grids, external dimensions) 2. Appearance (defects that should not be present: exposed fibers, whitening, pits, fractures, uneven fibers, etc.) 3. Barcol hardness 4. Concentrated load and uniformly distributed load 5. Resin content 6. The simplest and most practical method to identify fiberglass quality: place the fiberglass upright on a cement or tile floor; if you hear a crisp metallic sound, it indicates that the fiberglass is qualified. Beihai Yueda Fiberglass Products Co., Ltd. in Guangxi is a professional manufacturer of fiberglass products, and our products are well-received by users. We welcome inquiries.

2023/10/17

How to prevent the surface of fiberglass from wrinkling, becoming sticky, or developing pinholes?

In the process of manufacturing fiberglass products, improper operation may lead to issues such as wrinkling, pinholes, and stickiness on the surface of the fiberglass products. Let's understand the causes of these phenomena and the measures to prevent them. 1. Wrinkling of fiberglass products often occurs in the gel coat layer. If the first coat of gel coat has not completely gelled before applying the second layer, the styrene in the second layer may dissolve the first layer, causing swelling and resulting in wrinkles. Solutions: 1) Appropriately increase the working environment temperature. When applying the first layer of gel coat, use infrared bulbs to dry it before applying the second layer. Wait for the gel coat layer to gel before applying the layer resin; 2) Appropriately increase the amount of initiators and accelerators; 3) Control the environmental temperature in the workshop, ideally between 18-20°C. 2. Stickiness on the surface of fiberglass products during production is often due to the products being exposed to humid air or direct airflow from exhaust equipment like blowers or fans, causing excessive evaporation of styrene, which ultimately leads to a lack of wax-free resin in the layer, resulting in stickiness. Solutions: 1) Avoid producing products in low temperature or humid conditions; 2) Add 0.02% paraffin to the resin to prevent the polymerization effect of oxygen in the air; 3) Control the direction of ventilation to avoid drafts and reduce the evaporation of crosslinking agents; 4) Adjust the amount of initiators and accelerators based on the indoor environmental temperature; 5) Alternatively, use paraffin resin directly for operations. 3. Pinholes on the surface of fiberglass products are mainly caused by small bubbles entering the gel coat layer before gelling, dust on the mold surface, or high viscosity when adding flame retardants, leading to the evaporation of the solvent and leaving pinholes. Solutions: 1) Use a roller for impregnation during the molding process to eliminate bubbles; 2) Add suitable defoamers, such as silicone oil, to the resin; 3) Control the working environmental conditions, avoiding excessive humidity and ensuring that high temperatures are not too low; 4) The amount of catalyst should not be excessive to avoid premature gelling and bubble formation; 5) Ensure that materials are not damp; if they are, they need to be dried; 6) Keep the mold surface clean. These are the causes and preventive measures for issues such as wrinkling, pinholes, and stickiness on the surface of fiberglass products. We hope this information is helpful. Guangxi Fiberglass Products Co., Ltd. is a professional manufacturer of fiberglass products, and our products are well-received by users. We welcome inquiries by phone.

2023/09/05

Applications of Fiberglass Reinforced Plastic

Fiberglass Reinforced Plastic (FRP) generally refers to reinforced plastics made from glass fiber reinforced unsaturated polyester, epoxy resin, and phenolic resin matrix, using glass fiber or its products as reinforcement materials, commonly known as fiberglass reinforced plastic or fiberglass. In the past fifty years, the fiberglass industry has developed rapidly and is an important part of the composite materials industry. Seventy percent of the glass fiber production is used to manufacture fiberglass. Fiberglass is lightweight and hard, non-conductive, stable in performance, has high mechanical strength, and is corrosion-resistant. It is used in jet aircraft for fuel tanks and pipelines, which helps reduce the weight of the aircraft. The astronauts who landed on the moon carried mini oxygen tanks made of fiberglass. Fiberglass is easy to process, does not rust or rot, and does not require painting. In our country, fiberglass has been widely used to manufacture various small boats, lifeboats, yachts, and in the automotive industry, saving a significant amount of steel. Chemical plants also use fiberglass made from synthetic resin materials to replace stainless steel for various corrosion-resistant equipment, greatly extending the lifespan of the equipment. Fiberglass is non-magnetic and does not block electromagnetic waves, making it ideal for missile radar covers, akin to giving missiles protective glasses that do not obstruct the radar's "sight" while providing protection. Entering the 21st century, due to the excellent wave transmission properties of fiberglass, and with the widespread popularity of mobile communications, fiberglass has been widely used in the manufacture of 2G and 3G antenna covers. Its good formability and aesthetic appeal have contributed to beautifying communities, with products such as square column line covers, simulated stones, and beautifying trees for outdoor applications. Additionally, fiberglass has made significant contributions to improving sports performance. With the emergence of new fiberglass poles, records have soared due to their lightweight and elasticity, with the current pole vault record exceeding 6 meters. Today, fiberglass is also widely used in people's daily lives, affectionately referred to as "fiberglass". Due to certain special varieties that retain many advantages of glass, such as transparency, it is used for doors and windows, blocking UV rays while brightening living spaces. It is also used to make various sturdy and durable daily necessities, such as bathing products, kitchen utensils, and grooming tools. Guangxi Fiberglass Products Co., Ltd. is a manufacturer specializing in the production of fiberglass pipes, tanks, and other products, which are well-received by users. We welcome inquiries by phone.

2023/06/29

What are the applications of fiberglass reinforced sand pipes?

In China, Taiwan Province was one of the earliest places to manufacture and use fiberglass reinforced sand pipes. In the 1960s, it was used in the paper and chemical industries. Currently, the development and application of this product have become mature. Experts suggest that it can be prioritized for promotion and application in various engineering projects such as water supply, wastewater treatment, ventilation, refrigeration, water conservancy, and electricity.

2023/05/11

recommend News