Product classification

FRP storage tanks are a type of fiberglass product, primarily made from fiberglass as a reinforcement and resin as a binder, manufactured through a winding process controlled by a microcomputer. FRP storage tanks have properties such as corrosion resistance, high strength, lightweight, and long service life. Additionally, due to their flexible design capabilities and strong processability, they can be tailored for use in various industries such as chemical, environmental protection, food, and pharmaceuticals, gradually replacing carbon steel and stainless steel in many market sectors.

Integrated prefabricated pump station made of fiberglass

The integrated prefabricated pump station made of fiberglass consists of a top cover, fiberglass cylinder, base, submersible pump, working platform, and pipelines, designed to meet the requirements for boosting and draining water. It is mainly used in municipal water supply and drainage, drainage of low-lying roads, building water supply and drainage, and agricultural irrigation. It can systematically address issues such as leakage, corrosion, and pump failures commonly found in traditional pump stations, as well as a series of problems related to sludge settlement and environmental pollution, which often involve frequent maintenance and high costs.

Fiberglass septic tanks are mainly suitable for the treatment of domestic sewage in industrial enterprise living areas and urban residential communities.

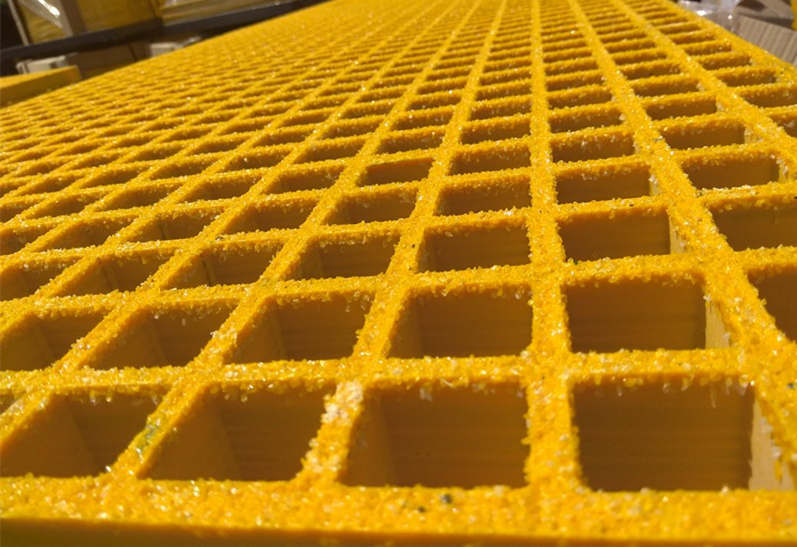

Fiberglass reinforced plastic grating

Fiberglass grating, also known as fiberglass grid plate, is a type of sheet material made from fiberglass as the reinforcing material and unsaturated polyester resin as the matrix, processed through special composite techniques to create a board with many voids. It features characteristics such as corrosion resistance, flame retardancy, non-magnetic insulation, vibrant colors, and a variety of styles available for selection.