Product classification

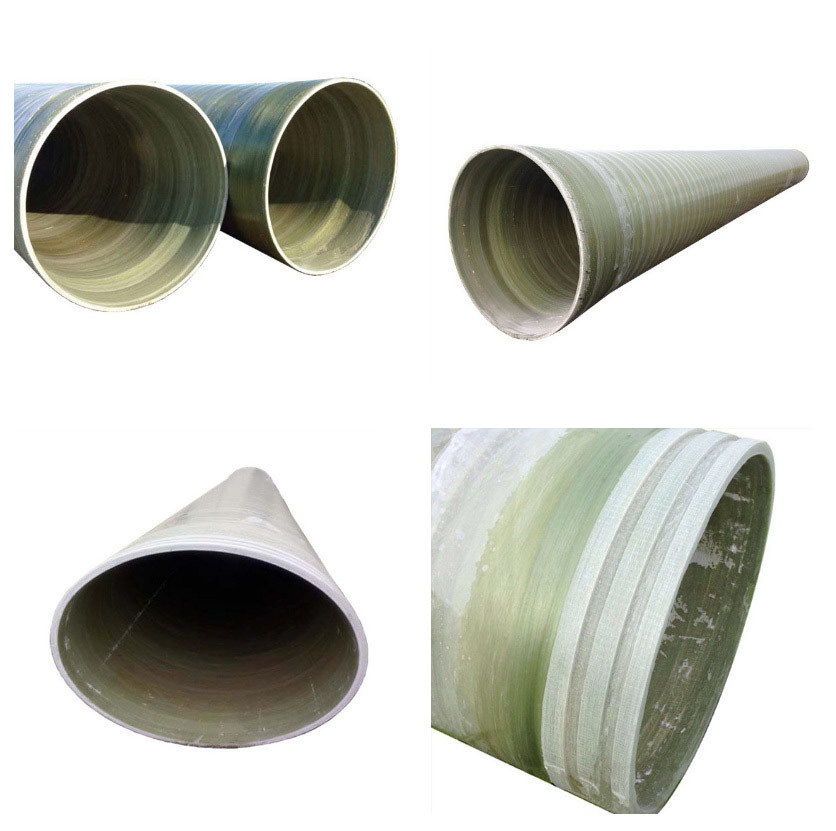

Fiberglass reinforced plastic sewage pipe

- Product Description

- Product Parameters

-

Advantages of fiberglass sewage pipes:

1. Excellent corrosion resistance

It has excellent mechanical properties and processing characteristics, resistant to most untreated sewage of acids, alkalis, salts, seawater, corrosive soil or groundwater, and many chemical substances.

2. Good heat and cold resistance

At -30°C, it still has good toughness and very high strength, can be used for a long time in the range of -50°C to 80°C, and can also be used at 110°C with specially formulated resin.

3. Good wear resistance

Tests have shown: water containing a large amount of mud and gravel was placed in the pipe for rotational wear comparison tests. After 300,000 rotations, the wear depth of the inner wall of the pipe was as follows: steel pipe coated with tar and porcelain oil was 0.53mm; surface-hardened steel pipe was 0.48mm; fiberglass pipe was 0.21mm, which indicates that fiberglass pipes have very strong wear resistance.

4. Pollution resistance after curing

During use, it does not scale, rust, or get contaminated by marine or sewage microorganisms such as shellfish and bacteria.

5. Few joints, high installation efficiency

The length of the pipes is generally: 6-12m per piece (special lengths can also be produced according to customer requirements). The long length of a single pipe and fewer joints speed up the installation, reduce the probability of failure, and improve the overall installation quality of the pipeline.

6. Small specific gravity, light weight

The sand-clad fiberglass pipes produced by fiber winding have a specific gravity of 1.65-2.0, only 1/4 of that of steel, but the circumferential tensile strength of fiberglass pipes is 180-300MPa, and the axial tensile strength is 60-150MPa, similar to alloy steel. Therefore, its specific strength (strength/specific gravity) is 2-3 times that of alloy steel, allowing it to be designed to meet various internal and external pressure requirements according to user needs. For the same pipe diameter, the weight of FRPM pipes is only 1/2.5 that of carbon steel pipes (steel plate rolled pipes), 1/3.5 that of cast iron pipes, and about 1/8 that of prestressed reinforced concrete pipes, making transportation and installation very convenient.

7. Good mechanical properties, excellent insulation performance

The tensile strength of the pipes is lower than that of steel, higher than that of ductile iron pipes and concrete pipes, while the specific strength is about 3 times that of steel pipes, 10 times that of ductile iron pipes, and 25 times that of concrete pipes. In addition, its thermal conductivity is only 1% of that of steel pipes, providing excellent insulation, suitable for use in areas with dense power transmission and telecommunications lines and high lightning frequency.

8. Excellent hydraulic performance, energy-saving

Sand-clad fiberglass pipes have a smooth inner surface, suitable for large diameter (≥φ500mm) water supply pipelines, with a small friction coefficient and good hydraulic fluid characteristics, and the larger the diameter, the more obvious the advantages. Compared to other pipe materials, sand-clad fiberglass pipes can significantly reduce head loss during water transport, saving pump power and energy.

9. Long service life, safe and reliable

According to simulation tests: the lifespan of sand-clad fiberglass pipes for general water supply and drainage can reach over 50 years, which is twice that of steel and concrete pipes. For highly corrosive media, its service life is much longer than that of steel pipes.

10. Flexible design, strong product adaptability

Sand-clad fiberglass pipes can be manufactured in various specifications, pressure ratings, stiffness levels, or other special properties according to users' various special requirements, making them widely applicable.

11. Low operation and maintenance costs

Due to the excellent corrosion resistance of fiberglass products, there is no need for rust prevention, pollution prevention, insulation, or thermal insulation measures and repairs, and buried pipes do not require cathodic protection, saving a lot of maintenance costs.

12. Good overall engineering benefits

The overall benefits of fiberglass pipes are desirable, especially as the diameter increases, the cost decreases. When further considering that buried pipes can be used for several generations without annual maintenance, their superior overall benefits can be fully realized.Product Show

Key words:

Product Consulting

Note: Please leave your mobile phone number and email address, our professionals will contact you as soon as possible!