What are the connection methods for fiberglass reinforced plastic (FRP) sand-filled pipes?

Release time:

2022/02/21

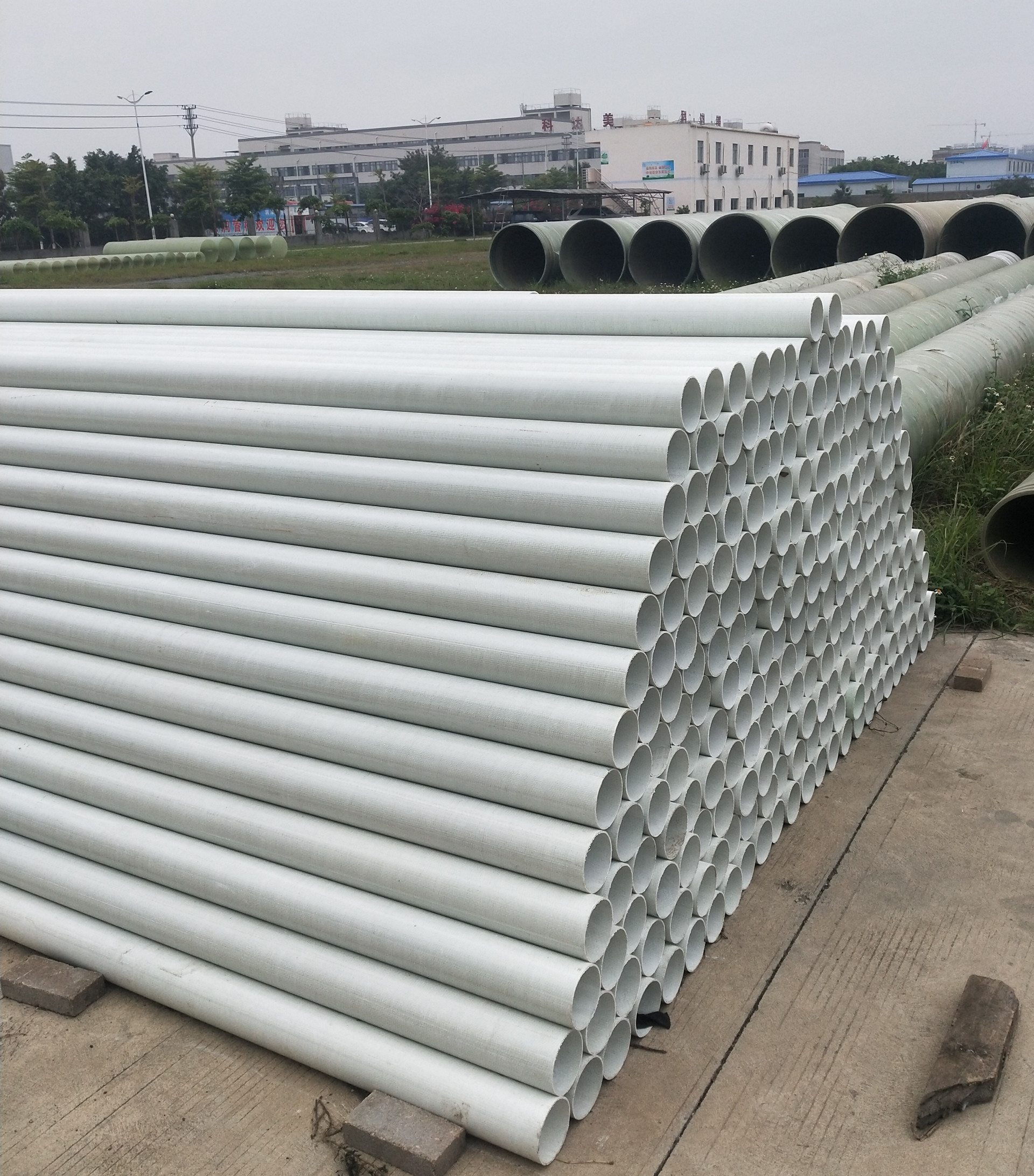

Fiberglass reinforced sand pipes generally use socket seal connections, which are quick and accurate, saving time and effort. In addition, there are various installations for pipes of different diameters, maintenance of damaged glass fittings, rigid constraint socket bonding, installation connections for pipes with diameters ranging from 50mm to 400mm, detachable rigid flange connections, and connections between glass pipes and steel pipes and equipment with diameters below 1200mm.

Glass fiber reinforced sand pipeGenerally, socket sealing connections are used, which are quick and accurate, saving time and effort. In addition, there are various installations for pipes of different diameters and repairs for damaged pipes with glass fittings, rigid constraint socket bonding, installation connections for pipes with diameters ranging from 50mm to 400mm, removable rigid flange connections, and connections between glass pipes and steel pipes and equipment with diameters below 1200 mm.

Glass fiber reinforced sand pipeThe connection uses a plug-in sealing method, which is quick and accurate, saving time and effort. In special cases, flange connections can also be used. The single seal of the glass fiber reinforced cable pipe connects with the double O-ring of the glass fiber reinforced sand pipe. Long-span bridges tell us that the connection methods of FRP pipes are quite common. The single seal of FRP cable pipes connects with the double O-ring of FRP sand pipes, and the connection method of epoxy high-pressure pipes is more common. The pipe connection consists of a dedicated rubber lining and a glass fiber reinforced polyester outer wall, composed of two parts. Full surface thermal (positive and complementary) cross-linking can provide reliable mechanical properties, corrosion resistance, and sealing performance. Generally, socket sealing connections are quick and accurate, saving time and effort. Flange connections can also be used.

1. Single seal connection. Suitable for medium and low-pressure buried pipelines.

2. Double seal sleeve connection. Suitable for single interface pressure testing of high-pressure underground buried pipelines.

3. Socket connection. Suitable for high-pressure, complex load large-diameter pipes.

4. Butt joint: Suitable for high and low-pressure pipe and fitting connections, L and T depending on the situation.

The sealed nylon rod key lock is mainly used for axially pulled pipes, such as deep well pipes.

5. Flange connections are suitable for medium and low-pressure fittings, pipe and equipment connections, and are applicable to standards such as Hg, JB, GB, ASTM, DIN, NF, JIS, etc.

Glass fiber reinforced sand pipeSuitable for various environments and widely used. They have ventured into all fields and are still expanding. Glass fiber reinforced sand pipes come in various types and applications, but the development prospects are very promising.

Uses: Used in urban sewage treatment, water supply and tap water transportation, farmland irrigation, petrochemical and various other industries.

Used for transporting medium and low-pressure clean water, raw water, and sewage. Generally, when the pressure exceeds 10 kilograms, no officer is required.

The length of the pipes is usually 6 meters, with 4 meters being more common for each pipe. The length of a single pipe is shorter, with fewer joints, faster installation speed, lower failure probability, and better overall installation quality.

The glass fiber reinforced drainage pipes are generally 12m, 6m, and 9m, with the top pipe clamp pipes being 3m and 2m (special length pipes can also be made according to customer requirements).

After the pipe connection is successful, water pressure testing and backfilling measures should be taken to prevent the pipes from being affected and deformed by various factors. During the backfilling process, effective backfill materials should be selected and the pipe area should be compacted according to design requirements. Before the backfilling work begins, debris in the trench should be cleared, and standing water should be removed. If the upper layer of the pipe is relatively shallow, the actual supporting force of the pipe will continue to decrease, and the pressure load will continue to increase. Therefore, construction companies can negotiate with design units to replace the original backfill materials and choose stronger backfill materials such as lime soil, sand, and gravel. When the pipe passes through obstacles, its deep requirements should be analyzed, its design requirements should be analyzed, and corresponding pipe protection forms should be taken.