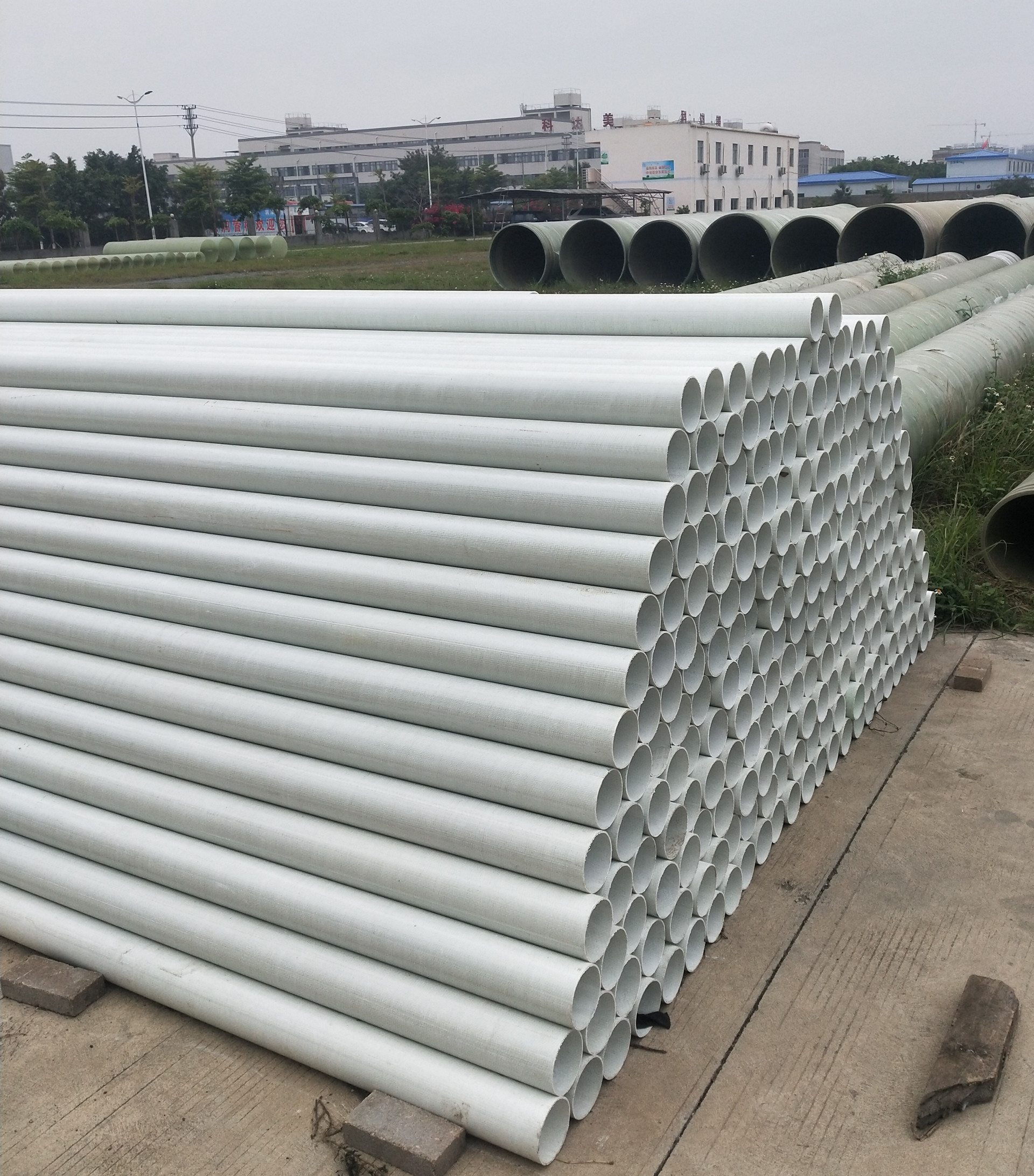

The application and characteristics of fiberglass reinforced sand pipes.

Release time:

2021/12/22

Fiberglass reinforced sand pipes are suitable for different environments. Let's understand the use of fiberglass reinforced sand pipes in various environments. Depending on the different corrosive environments, different anti-corrosion resins can be selected for fiberglass reinforced sand pipes, mainly including: isophthalic unsaturated polyester resin, vinyl ester resin, bisphenol A resin, epoxy resin, and furan resin.

Glass fiber reinforced sand pipeSuitable for different environments. Let's take a look.Glass fiber reinforced sand pipeUsage in different environments.According to different corrosive environments,Glass fiber reinforced sand pipedifferent anti-corrosion resins can be selected, mainly: isophthalic unsaturated polyester resin, vinyl resin, bisphenolA resin, epoxy resin, furan resin, etc. Choose according to specific conditions: for acidic environments, use bisphenol A resin and furan resin; for alkaline environments, use vinyl resin, epoxy resin, or furan resin. For solvent-type environments, choose furan and other resins. When the corrosion from acids, salts, and solvents is not severe, lower-cost isophthalic resin can be used. By selecting different resins for lining, glass fiber reinforced pipes can be widely used in working environments such as acids, alkalis, salts, and solvents, showing good corrosion resistance.

Glass fiber reinforced sand pipeIt has the following characteristics.

First, it uses centrifugal casting to create a solid high-density pipe wall,Glass fiber reinforced sand pipetheouter surface of the glass reinforced part of the pipe wall is smooth, with no scale attachment, low head loss, high pipe strength, and pressure resistance up to20 ~ 24 tar;

Second, the joints are convenient, and installation is simple. The pipe ends are open and can be cut on-site at any position. The loose joints made of neoprene and glass fiber can withstand longitudinal pressure or tension in various situations.

Third, it has strong corrosion resistance, and the inner and outer walls of the pipe do not require anti-corrosion treatment, with a theoretical service life of over50 years, and no electrolysis corrosion issues;

Fourth,glass fiber reinforced sandpipes are lightweight, only10% of the same diameter concrete pipes, and 20% of metal or asbestos cement pipes;

Fifth,Glass fiber reinforced sand pipeit has a wide range of applications, can withstand70 high temperatures, can be used for transporting industrial water and drinking water, sewage, and corrosive industrial wastewater or seawater, can be installed on the ground or buried underground or even under the sea, and can be installed in various harsh environmental climates and terrain conditions, with good performance;

Sixth,complete fittings, can match with pipes of any material, and any part of the pipe can be drilled.

With the continuous growth of China's industrial sector,Glass fiber reinforced sand pipethe application is becoming more common. The following are the characteristics and applications of glass fiber reinforced sand pipes:

1. The sealing performance of the joints is very good, with no signs of leakage or damage, increasing the quiet and reliable performance of water supply.

2. Strong water resistance and corrosion resistance: manufacturers use good steel asGlass fiber reinforced sand pipethe raw material for the pipes, improving corrosion resistance, saving consumers from later anti-corrosion costs, and saving time and effort.

3. Good mechanical properties: glass fiber reinforced pipes pass acceptance tests, do not scale, do not require cleaning, and will not pollute water quality again.

4. Good pressure resistance: pipes and fittings are planned and manufactured according to the pressure requirements of the process, and water pressure tests are conducted at 1.5 times the required pressure.

5. Non-toxic and harmless: can transport drinking water, protecting health.