The price of fiberglass grating is influenced by several key factors.

Release time:

2020/11/05

Fiberglass grating can be widely used in industries such as petroleum, chemical electronics, electric power, paper making, dyeing, electroplating, marine exploration, and wastewater treatment for work platforms, equipment platforms, drilling platforms, walkways, etc. Its price is calculated per square meter, and there are various factors that determine the price of fiberglass grating. The main factors affecting the price of fiberglass grating boards include the thickness of the grating board, the raw materials used, the surface type of the grating board, and any special requirements for the medium used. 1. First, starting from the raw materials, the two main raw materials for fiberglass grating boards are resin and fiberglass, with fiberglass being divided into medium-alkali and alkali-free.

Fiberglass grating can be widely used in industries such as petroleum, chemical electronics, electric power, paper making, dyeing, electroplating, marine exploration, and sewage treatment for work platforms, equipment platforms, drilling platforms, walkways, etc. Its price is calculated per square meter, and there are various factors that determine the price of fiberglass grating. The main factors affecting the price of fiberglass grating boards include the thickness of the grating board, the raw materials used, the surface type of the grating board, and any special requirements for the medium used.

1. First, starting from the raw materials, the two main raw materials for fiberglass grating boards are resin and fiberglass. Fiberglass is divided into medium-alkali and alkali-free types, with the alkali-free type being relatively more expensive. There are many types of resin, and the appropriate resin is selected based on the specific usage scenario. For example, in a chemical plant, a resin with strong corrosion resistance is generally chosen; in a boiler factory, a resin with extremely high heat resistance is generally selected. The price will vary depending on the raw materials used.

2. Next, the size and thickness of the fiberglass grating board. The length and width of the molded grating cover board are fixed at 3.66m and 1.22m, respectively, and the price varies based on thickness. Of course, the thicker the board, the higher the load-bearing capacity.

3. The surface type of the fiberglass grating board; fiberglass grating is divided into ordinary type and cover type.

The price of ordinary fiberglass grating is generally around 200 per square meter.

(1) Concave surface (naturally formed): Concave surface grating is basically anti-slip.

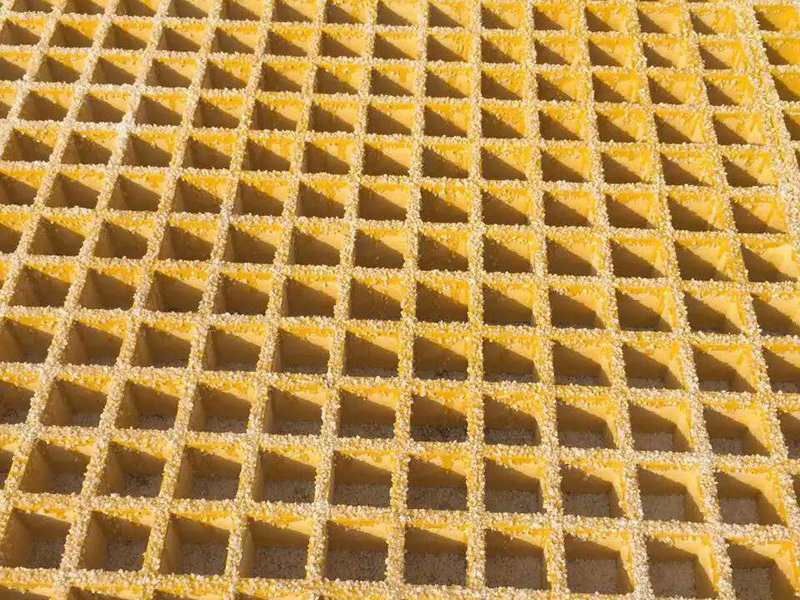

(2) Sanded surface: Sanded grating is particularly anti-slip.

(3) Smooth surface (surface polished): Smooth surface grating is not anti-slip and is generally used for decoration and other scenarios requiring a smooth surface.

The fiberglass cover type is used in situations where there can be no holes, to prevent liquid leakage, gas evaporation, or where there are special requirements for holes. Due to the larger amount of material used, the cover type fiberglass grating is relatively more expensive.

(1) Smooth cover grating: The surface is not anti-slip and is easy to dust.

(2) Quartz sand surface cover grating: Sand surface cover grating has the best anti-slip properties.

(3) Patterned cover grating: Patterned cover grating has slightly worse anti-slip properties but is more aesthetically pleasing.

Guangxi Fiberglass Products Co., Ltd. is a professional manufacturer of fiberglass grating. Welcome to purchase..