Hotline:15078906688

E-mail:282911489@qq.com

- All

- Product Management

- News

- Introduction

- Enterprise outlets

- FAQ

- Enterprise Video

- Enterprise Atlas

Hotline:

Blog

BEIHAI YUEDA FRP PRODUCTS

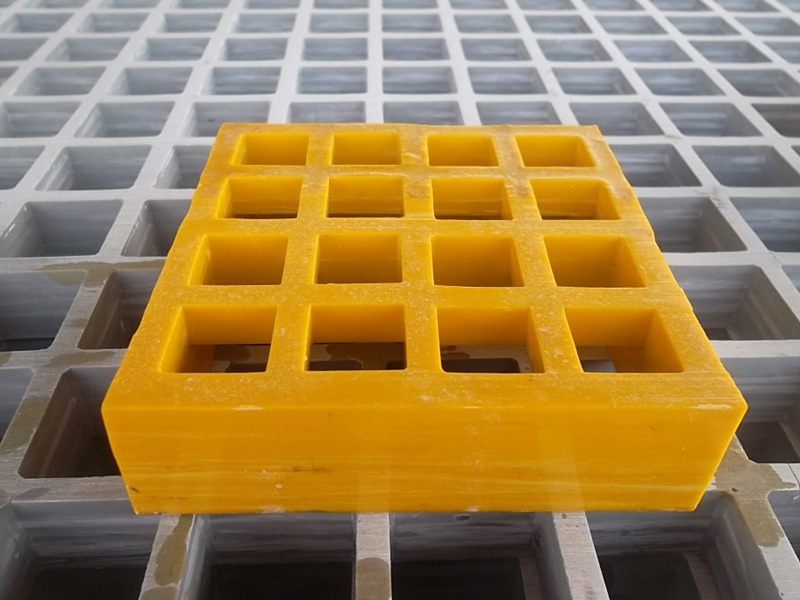

Understanding fiberglass grating covers from multiple aspects

Release time:

2020/10/22

The specifications of fiberglass grating cover plates sold on the market vary widely, and the brands, types, and quality are also inconsistent. This makes it difficult for consumers to make choices during the purchasing process. How can one select a high-quality, cost-effective, and reasonably priced fiberglass grating cover plate among numerous brands? The manufacturing methods of fiberglass grating cover plates currently available on the market mainly include three different production processes: reciprocating fiber winding process, centrifugal casting process, and continuous fiber winding process. The application of fiberglass grating cover plates is at least not limited to the petrochemical industry.

The specifications of fiberglass grating cover plates sold on the market vary, and the brands, types, and quality are also uneven, which makes it difficult for consumers to choose during the purchasing process. How can one select a high-quality, cost-effective, and affordable fiberglass grating cover plate among so many brands?

1. Manufacturing methods of fiberglass grating cover plates

Currently, there are three main production processes for different specifications of fiberglass grating cover plates on the market: reciprocating fiber winding processing, centrifugal casting processing, and continuous fiber winding processing.

2. Usage locations of fiberglass grating cover plates

In the petrochemical industry, the use of fiberglass grating is indispensable. The oil industry utilizes its corrosion resistance because oil stains are characterized by excessive dirt. Using fiberglass grating cover plates can better handle this situation. In the chemical industry, fiberglass grating cover plates are also used for handrails, stairs, work platforms, corridors, and drainage systems.

3. Precautions for using fiberglass grating cover plates

How should fiberglass grating cover plates be used? Different specifications of fiberglass grating cover plates correspond to different usage spaces. How to determine which specification of fiberglass grating cover plate should be used in different spaces? In sewers or wastewater treatment projects, small specifications of fiberglass grating can be used. Due to their good corrosion resistance, they generally do not corrode even when buried underground for fifty years, and they are also used in the underground pipeline installation industry. This saves the annual inspection and maintenance work.

Beihai Yueda FRP Products

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.

WeChat Public Number

Mobile website

Contact Us

Telephone:0779-2096111

Mailbox:282911489@qq.com

Address: 200 m north of the intersection of Hong Kong Road and Southwest Avenue in Beihai Industrial Park

©2023 Guangxi Beihai Yueda FRP Products Co., Ltd. All rights reservedSEO Tags